Indian-road-based vehicle performance and safety mainly depend upon the quality of their components, one of which is the wheel rim. Car rims play a crucial role in vehicle stability, load-carrying capacity, and overall vehicle efficiency. For the sake of standardised production and consumer safety, the Bureau of Indian Standards has developed IS 9436:2018 as the requirement standard for passenger car rims.

In this blog, we will cover everything that you must know about BIS Certification for Rims for Cars, from its significance, documentation, test parameters, procedure, and how ELT Corporate can assist you in achieving hassle-free compliance.

What is BIS Certification?

BIS Certification is a quality management system operated by the Bureau of Indian Standards, which is the national standards body of India. The system guarantees that the product conforms to Indian Standards with regard to safety, quality, and performance.

Whether BIS certification is voluntary or mandatory is determined by whether the product falls under a Quality Control Order (QCO). BIS certification is compulsory for car rims based on government notifications.

Read More: Introduction To Bureau Of Indian Standards

Is BIS Certification of Rims for Vehicles Mandatory

Yes, passenger vehicle rims are subject to BIS Certificate under Automotive Industry Standards (AIS) and controlled through QCOs of the Ministry of Road Transport & Highways (MoRTH).

Under the current regulatory regime:

- Certification to IS 9436:2018 is mandatory.

- Manufacturers and importers have to comply before the sale of the product.

- Non-compliance will attract a penalty, product recall, or market ban.

- Scope of IS 9436:2018 – Passenger Car Rims Performance Requirements

IS 9436:2018 covers performance requirements and testing methods for all types of rims used in passenger cars. These are:

- Pressed steel rims

- Light alloy rims (aluminium/magnesium)

- Welded and single-piece rims

Key parameters under IS 9436:2018:

- Dimensional tolerances

- Dynamic cornering fatigue test

- Radial fatigue test

- Impact test

- Surface finish and coating durability

- Heat resistance and load deformation

- Air leakage (for tubeless rims)

Benefits of BIS Certification of Rims for Vehicles

Below, we mentioned some benefits of BIS Certificate of rims for vehicles:

- Regulatory Compliance

- Meets Indian safety standards under MoRTH & BIS Act

- Roadworthiness

- guarantees safety and mechanical performance during harsh driving conditions

- Consumer Trust

- The ISI mark inspires confidence in the reliability of the product

- Market Access

- allows for sale through OEMs, dealerships, and online shopping

- Export Eligibility

- Enables export to countries accepting Indian Standards

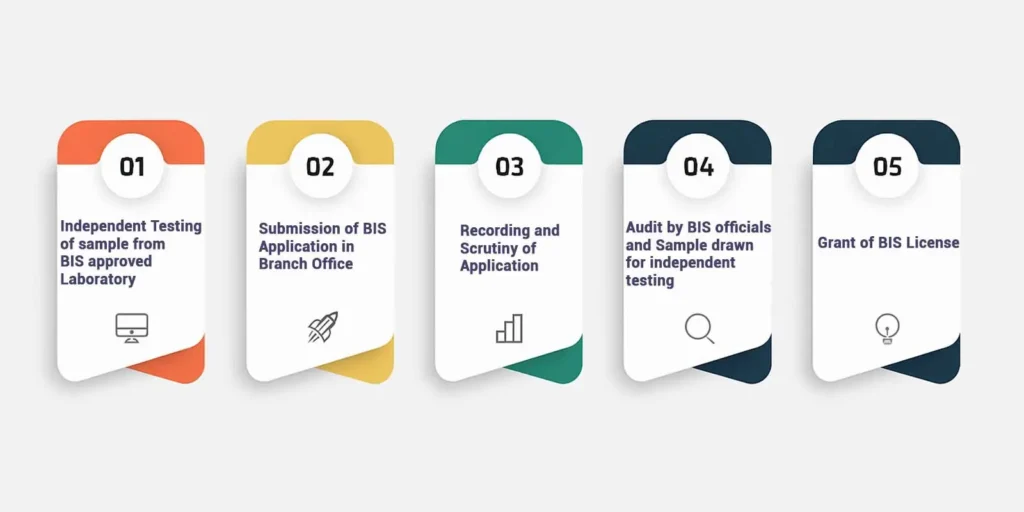

Step-by-Step Process for BIS Certification of Rims for Vehicles

Here is a simplified summary of the BIS Certificate of rims for vehicles process:

Step 1: Identification of the standard: Check whether your product category falls under the IS 9436:2018 scope. Cross-check dimensions, type of alloy, and performance standards.

Step 2: Application on the BIS Portal: Access Manak Online Portal

Apply for Form VI for Indian manufacturers or Form I under FMCS (for foreign manufacturers)

Pay government fees

Step 3: Product Testing: Provide rim samples for testing to a BIS-approved laboratory. Key tests include:

Dynamic cornering fatigue

Radial load fatigue

Impact resistance

Heat & air retention testing

Step 4: Factory Audit: BIS officials conduct factory inspections to assess:

Machinery and quality control

SOPs on the production line

In-house testing facility, if available

Batch traceability and documentation

Step 5: Issuance of ISI License

Following lab test clearance and audit clearance, BIS issues the ISI Mark License, which allows certified markings on the product.

Read More: Process for getting BIS for Certification

Documents Required for BIS Certification of Rims for Vehicles

Below, we mentioned some required documents for BIS Certification of rims for vehicles:

- Company Documents Certificate of Incorporation, GST, PAN, IEC (for exporters)

- Manufacturing Details: Plant layout, machine list, QC flow

- Technical Sheet: Material grade, drawings, alloy% % details

- Test Reports

- BIS-approved lab test reports (IS 9436:2018)

- Quality Manual

- SOPs from raw material to final inspection

- Location Documents: Factory lease/rent agreement, electricity bill

- Authorised Signatory Proof

- ID, Board Resolution, Power of Attorney

- Fees & Cost Breakdown

Read More: Documents Required For BIS Registration

Fee Component Approx. Cost (INR)

Varies depending on the validity period

Renewal and Surveillance

Post-certification, the manufacturer is required to:

- Renew the license every 1–2 years

- Undergo BIS surveillance audits annually

- Maintain production records and test reports

- Send market samples whenever necessary by BIS

- Compliance with ISI logo usage

- Non-compliance may lead to suspension or cancellation of the license.

Consultants’ Role in BIS Certification of Rims for Vehicles

It can be tough to deal with technical standards, product testing, and audit preparedness. An experienced BIS consultant helps you with :

- Understanding of the IS 9436:2018 test parameters

- Coordination of labs and documentation

- Enable factory readiness for audit

- Verify proper portal filings and compliance timelines

- An experienced consultant minimises rejection risk and streamlines certification.

Effect of BIS Certification of Rims for Vehicles on the Market of Automotive

Below we mentioed some effects of BIS Certificate of Rims for Vehicles:

- BIS Certification is regulatory, yet it also affects purchasing choice and market visibility:

- Helps OEMs and Tier-I suppliers choose compliant vendors

- Enables listing on government procurement portals (e.g., GeM)

- Enhances brand reputation among dealerships and retail buyers

- Decreases product recall risk from safety failure

How ELT Corporate Can Help You

We, at ELT Corporate, deal with comprehensive BIS certification solutions for automobile components, i.e.:

- Compliance review against standards (IS 9436:2018)

- Test support for samples with certified laboratory facilities

- Factory audit guidance

- Full documentation & online submission

- BIS portal support and post-approval assistance

- Whether you’re a domestic rim manufacturer or foreign exporter, we help you accelerate the process of certification with full legal adherence.

- Speak with our automotive compliance experts today!

Conclusion

BIS Certification of Rims for Vehicles under IS 9436:2018 is mandatory for all passenger car rims to guarantee performance, strength, and safety. By using the ISI mark, manufacturers and importers align their products to be regulatory compliant and roadworthy in India while gaining market credibility.

Investing in BIS certification is not just compliance—it’s an entry into new possibilities within the automotive sector.

Is BIS Certification of car rims mandatory in India?

Yes, it is mandatory under IS 9436:2018 as notified by MoRTH.

Can foreign manufacturers get BIS for rims?

Yes, they must apply under the Foreign Manufacturers Certification Scheme (FMCS).

How many days are required to get BIS certified?

Typically 4–6 weeks, depending on lab testing and audit readiness.